The revolution of additive manufacturing in biomedicine

On the occasion of the inauguration of the 2024/2025 academic year, the new 3D Innovation Lab, located in the Roberto Rocca Innovation Building, was officially launched

The mission of the 3D Innovation Lab is to drive innovation by developing cutting-edge solutions based on 3D printing technologies. The Lab fosters collaboration across clinical practice, scientific research, and university education, while promoting strategic partnerships with biotech companies and the industrial sector.

Led by Paolo Oliva, Head of Research Technology at Humanitas, the team includes biomedical researchers, bioengineers, and materials scientists. The Lab has already numerous collaborations ongoing with both preclinical and clinical research groups within the institute.

“Additive manufacturing, or 3D printing, is revolutionizing medicine and life sciences due to its ability to combine precision and speed: creating realistic models for preclinical training and replicating tissue structures not only at the macroscopic level, but also at the microscopic scale,” explains Paolo Oliva. “To achieve this, advanced technologies and an interdisciplinary approach are essential.”

A Unique Technological Ecosystem

The Lab is equipped with an array of state-of-the-art technologies, including:

- A 3D scanner capable of capturing high-definition images of three-dimensional objects—such as parts of the human body— that recapitulate both their geometry and their microscopic surface texture.

- A suite of 3D printers capable of producing life-sized organs using various resin types. These resins enable the creation of models with diverse aesthetic and mechanical properties, such as elasticity, strength, and porosity, enhancing medical training and supporting the testing of devices and drug delivery strategies

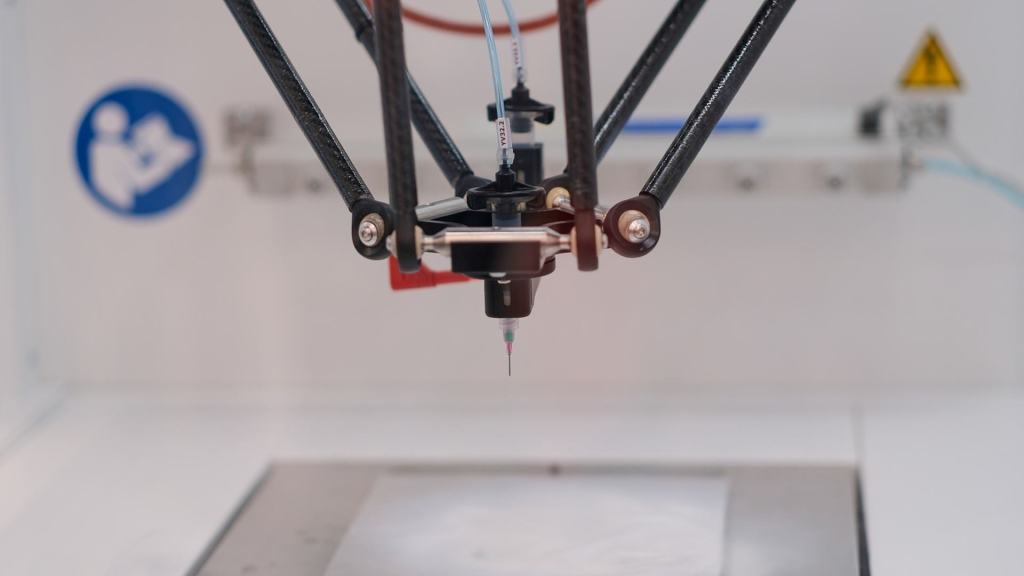

- The Electrospider 3D bioprinter, developed in collaboration with Bio3DModel (a SolidWorld Group subsidiary) and the University of Pisa. This printer creates three-dimensional cell cultures that better replicate human tissues, including tumors, where the 3D microenvironment plays a crucial role in pathological mechanisms.

- A bioindenter for analyzing the biomechanical properties of tissues, enabling accurate replication through 3D printing techniques. This technology is part of a lab directed by Professor Alessandro Zerbi, Head of Pancreatic Surgery at IRCCS Istituto Clinico Humanitas. Established three years ago in partnership with Politecnico di Milano, the lab focuses on studying and replicating the biomechanical properties of pancreatic tissue—an especially challenging organ for surgery – and is now located adjacent to the 3D Innovation Lab, to further foster collaborations and synergies.

Advanced Phantoms for Training

“Using the latest 3D printing technologies, the Lab creates high-fidelity models that replicate healthy and pathological tissues in intricate detail. These models are essential for training healthcare professionals in various procedures. Their realistic texture, along with anatomical and morphological accuracy, allows trainees to gain practical experience in scenarios that closely mirror reality, thereby enhancing their competence and confidence,” says Paolo Oliva.

Bridging the gap between theoretical knowledge and practical applications, these 3D-printed models play a vital role in improving medical training. The 3D Innovation Lab team collaborates closely with the Mario Luzzatto Simulation Center at Humanitas University, a 2,000-square-meter facility entirely dedicated to real-life medical simulation.

Addressing New Clinical Needs

Among its core objectives, the lab aims to develop patient-specific anatomical models to assist in surgical planning and execution for selected cases. These meticulously crafted models reflect the patient’s unique anatomical characteristics, providing surgeons with valuable insights for better planning and performing interventions.

“The Lab is currently in the process of obtaining certification to produce custom cutting guides for use during complex procedures. These bespoke guides are designed to enhance precision, reduce operating time, and improve clinical outcomes,” explains Paolo Oliva.

The Lab has already established multiple collaborations, particularly with units specializing in liver surgery, vascular and cardiac surgery, and breast surgery.

Tissue Engineering and Biofabrication

The 3D Innovation Lab also features a “wet” laboratory area equipped with tools and technologies—including the Electrospider bioprinter—for creating three-dimensional cell cultures with precise composition and architecture. The Lab also fabricates biological scaffolds that mimic the physical and mechanical properties of tissues.

This space is open to all Humanitas researchers looking to expand their in vitro models into three dimensions—a critical step for studying certain pathological processes. Among the first to collaborate in this area are the Neuroscience Development Lab, led by Simona Lodato, and the Precision Medicine Lab, led by Salvatore Piscuoglio.