Clinical Platforms

3D Innovation Lab

The 3D Innovation Lab aims at promoting the cross contamination among Hospital, Research, University and BioTech Companies while fostering personalized medicine solutions through additive manufacturing techniques. Our mission is to transform scientific discoveries into real, applicable solutions.

The challenge

Additive manufacturing, or 3D printing, is revolutionizing medicine and life sciences with its potential to bridge tissue engineering research and regenerative medicine, create realistic phantoms for preclinical training, and replicate human tissue structures at both macro and nano scales.

Main R&D activity

Clinical needs

Our state-of-the-art 3D printing lab is dedicated to revolutionizing surgical preparation and execution through the production of patient-specific anatomical models. These models are meticulously crafted to reflect the unique anatomical features of each patient, providing surgeons with invaluable insights and enhancing their ability to plan and execute procedures with unparalleled precision. In addition to anatomical models, we specialize in the creation of cutting guides tailored to support complex surgical interventions. These custom guides are designed to improve surgical accuracy, reduce operation time, and ultimately enhance patient outcomes.

Advanced training phantoms

By utilizing the latest 3D printing technology, we create high-fidelity models that replicate the intricate details of both normal and diseased tissues. These models are essential for training healthcare professionals in various procedures, from basic diagnostic techniques to complex surgical interventions. The realistic texture and anatomical accuracy of our phantoms ensure that trainees gain hands-on experience that closely mirrors real-life scenarios, thereby enhancing their competence and confidence.

By bridging the gap between theoretical knowledge and practical application, our 3D printed phantoms play a crucial role in improving patient care and outcomes. We are dedicated to pushing the boundaries of medical training and supporting the continuous development of healthcare professionals worldwide.

Tissue engineering and biofabbrication

Our laboratory is dedicated to advancing the field of tissue engineering through the biofabrication of scaffolds able to mimic the physical and mechanical properties of human tissues at both macro and nanoscale levels. We employ a range of innovative biofabrication techniques, including advanced 3D printing technologies, to precisely control the composition, architecture, and mechanical properties of the scaffolds. One of our key capabilities is the extrusion of hydrogels that contain living cells, which allows us to create bioactive constructs that support cell viability and function. Constructs we develop have wide-ranging potential applications in regenerative medicine, drug deliver, and disease modeling.

Collaborate with us

We invite researchers, companies, and institutions to join us on this journey toward technological and scientific advancement:

- Access to advanced research: by collaborating with us, you will have access to our latest and most innovative research, as well as the opportunity to participate in pioneering projects.

- Product and technology development: together, we can transform ideas into real, marketable products, reducing development time and costs.

- State-of-the-art infrastructure: our lab is equipped with the latest technologies, including advanced 3D printers, analytical tools, and cutting-edge design software.

- Multidisciplinary expertise: our team consists of experts in various fields, ready to work with you to tackle any technical or scientific challenge.

Contact Us

We are always looking for new partners and collaborators who share our passion for innovation and applied research. If you are interested in exploring collaboration opportunities, discussing a specific project, or simply learning more about what we do, please do not hesitate to contact us.

Machinery

We use high end technology of the latest industry standards

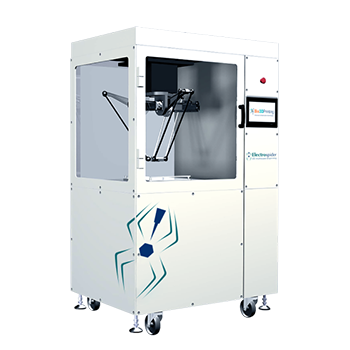

Electrospider

Epsilon W50

Form 3BL

iReal 2E 3D body scanner

J850 Digital Anatomy 3D printer

Prusa I3 MK3S

Selected publications

Wearable Health Technology for Preoperative Risk Assessment in Elderly Patients: The WELCOME Study.

3D bioprinting of multi-layered segments of a vessel-like structure with ECM and novel derived bioink.

Frozen Section Analysis and Real-Time Magnetic Resonance Imaging of Surgical Specimen Oriented on 3D Printed Tongue Model to Assess Surgical Margins in Oral Tongue Carcinoma: Preliminary Results.

4D printing in biomedical applications: emerging trends and technologies.

One-Pot Process: Microwave-Assisted Keratin Extraction and Direct Electrospinning to Obtain Keratin-Based Bioplastic.

Versatile and non-cytotoxic GelMA-xanthan gum biomaterial ink for extrusion-based 3D bioprinting.

Bioprinting for bone tissue engineering.

Shape-memory actuators manufactured by dual extrusion multimaterial 3d printing of conductive and non-conductive filaments.

Staff